In today’s competitive market, packaging is more than just a container it is a critical factor in product protection, customer satisfaction, and regulatory compliance. Packaging testing is the systematic process of verifying the integrity, durability, safety, and compliance of packaging materials and designs to ensure products reach consumers in optimal condition. This process is especially vital in sectors such as food, pharmaceuticals, and e-commerce, where packaging must safeguard product quality while meeting stringent regulatory standards.

What is Packaging Testing?

Packaging testing involves measuring various characteristics of packaging materials, components, and finished packages to assess their performance under real-world conditions. It includes physical, environmental, chemical, functional, and user experience tests to ensure packaging can withstand handling, transportation, storage, and consumer use. This testing helps verify compliance with industry specifications and regulations, protects product integrity, and enhances customer experience by ensuring packaging is safe, durable, and user-friendly.

Importance of Packaging Testing in Quality Assurance

For industries like food, pharmaceuticals, and e-commerce, packaging testing is crucial to:

- Protect Products: Prevent damage, contamination, and spoilage during shipping and storage.

- Ensure Safety: Confirm packaging materials are safe for consumer contact, especially for sensitive products like medicines and food.

- Achieve Regulatory Compliance: Meet legal and industry standards to avoid recalls and penalties.

- Support Sustainability: Evaluate eco-friendly materials for recyclability and biodegradability, aligning with environmental goals.

- Enhance Brand Reputation: Deliver products in perfect condition, reinforcing consumer trust and satisfaction.

- Optimize Costs: Identify opportunities for material efficiency and cost savings without sacrificing quality.

Types of Packaging Testing

Packaging testing encompasses several specialized types:

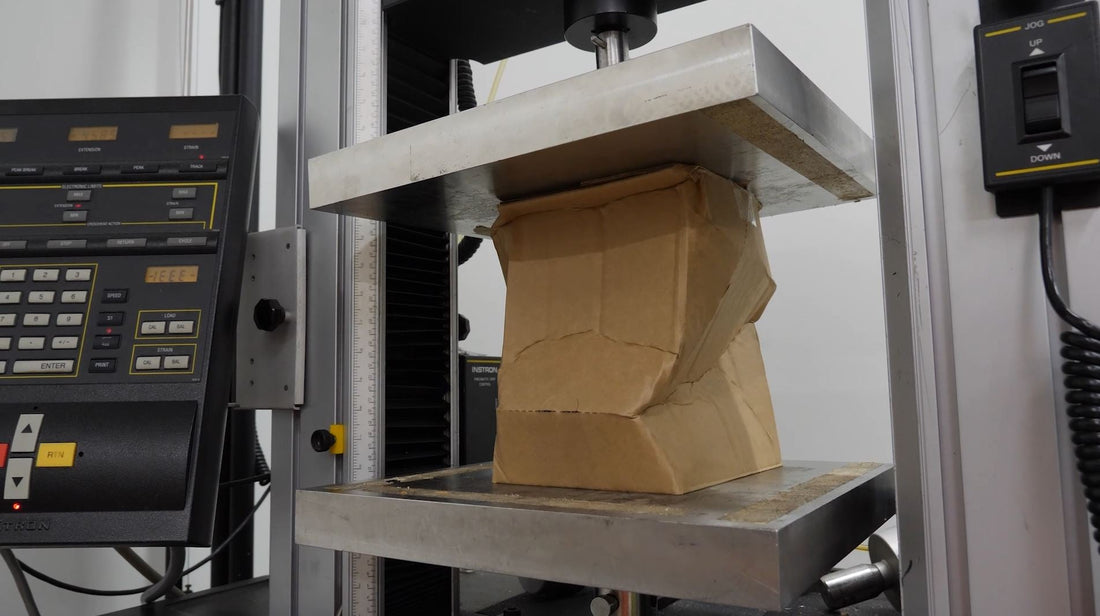

- Physical Testing: Drop, vibration, compression, shock, and puncture resistance tests simulate handling and transportation stresses.

- Environmental Testing: Temperature cycling, humidity, altitude simulation, UV exposure, and freeze-thaw tests assess packaging performance under varying environmental conditions.

- Chemical Testing: Evaluates the safety and suitability of packaging materials, especially for food and pharmaceuticals.

- Functional Testing: Assesses seal strength, peel testing, and package integrity to ensure protective barriers remain intact.

- User Experience Testing: Examines ergonomics, usability, and consumer interaction with packaging.

- Industry-Specific Tests: Tailored tests for sectors like medical devices, food safety, and e-commerce logistics.

How Packaging Testing Works

The packaging testing process typically follows these steps:

- Define Objectives: Identify testing goals based on product type, regulatory requirements, and environmental factors.

- Develop a Testing Strategy: Plan comprehensive tests prioritizing critical quality attributes.

- Select Testing Methods: Choose appropriate physical, chemical, environmental, and functional tests that simulate real-world conditions.

- Prepare Samples: Use representative packaging samples reflecting actual production.

- Conduct Testing: Perform tests in controlled environments using standardized protocols.

- Analyze Results: Compare outcomes against acceptance criteria to identify weaknesses or compliance issues.

- Report Findings: Document methods, results, and recommendations clearly.

- Implement Improvements: Modify packaging design or materials based on test feedback.

- Verify Changes: Retest to confirm effectiveness of improvements.

- Continuous Monitoring: Maintain ongoing quality assurance through periodic testing.

By understanding and implementing thorough packaging testing, professionals in food, pharma, and e-commerce sectors can ensure their packaging not only protects products but also complies with regulations and meets consumer expectations. Companies like Kimecopak provide essential support in testing eco-friendly packaging materials in Canada, helping businesses innovate sustainably while maintaining high standards of quality and safety.

Physical Testing

Vibration Test Packaging: Simulates transportation vibrations to ensure packaging protects contents during transit.

Drop Test: Assesses packaging’s ability to withstand impacts from drops at various heights.

Compression Test: Measures packaging strength under stacking pressure during storage and shipping.

Puncture Resistance: Evaluates packaging’s ability to resist penetration by sharp objects.

Tensile Strength: Tests the material’s resistance to tension and stretching forces.

Package Integrity Testing for Structural Resilience: Confirms the overall durability and robustness of packaging structures under stress.

Environmental Testing

Temperature and Humidity Testing: Examines packaging performance under varying climatic conditions.

Altitude Simulation: Tests packaging integrity under changes in atmospheric pressure, important for air transport.

UV/Weather Exposure: Assesses resistance to sunlight and weather elements that can degrade packaging.

Environmental Resistance of Packaging Materials: Evaluates long-term durability against environmental factors.

Chemical Testing

Chemical Compatibility: Ensures packaging materials do not react adversely with product contents.

Migration Testing: Detects any transfer of substances from packaging to product.

Permeability Testing: Measures the passage of gases or liquids through packaging materials.

Food Contact Safety and Regulatory Compliance: Verifies packaging meets safety standards for food contact.

Packaging Materials Testing for Chemical Resistance: Confirms materials withstand exposure to chemicals without degradation.

Functional Testing

Seal Integrity: Tests the strength and reliability of seals to prevent leaks and contamination.

Closure System Durability: Evaluates the performance of caps, lids, and closures under repeated use.

Barrier Properties (against moisture, oxygen, etc.): Measures packaging’s effectiveness in protecting contents from environmental factors.

Tamper-Evident Packaging Features: Ensures packaging shows clear evidence if tampered with, enhancing security.

User Experience Testing

Consumer Experience Simulation: Replicates real-world handling to assess packaging usability.

Sensory Testing: Evaluates tactile and visual appeal to consumers.

Ease of Use: Tests how easily consumers can open, close, and handle packaging.

Accessibility and Inclusive Packaging Design: Assesses packaging for usability by people with disabilities or special needs.

Industry-Specific Packaging Tests

Food Packaging Testing: Includes leak and hygiene validation to ensure safety and freshness.

Pharmaceutical Packaging Testing: Focuses on blister integrity and contamination prevention.

Hazardous Materials Packaging Testing: Ensures compliance with strict safety regulations for dangerous goods.

E-commerce Packaging Testing: Covers drop, crush, and ISTA protocols to withstand online order logistics.

Packaging Testing Standards

Overview of Global and Industry-Specific Standards: Provides frameworks for consistent testing.

ASTM Packaging Test Methods: Widely used standards for physical and chemical testing.

ISO Packaging Standards: International standards covering various packaging aspects.

ISTA Transport Simulation Standards: Protocols simulating real-world transportation stresses.

When and How to Apply These Standards in QA: Guidance on integrating standards into quality assurance processes.

Advanced Testing vs Innovation

Non-Destructive Testing: Techniques that preserve packaging samples while assessing quality.

Digital Simulation & AI-Assisted Packaging Analysis: Using technology to predict packaging performance and optimize design.

Accelerated Aging Test: Simulates long-term storage effects in a shorter time.

Sustainable Packaging Testing: Focuses on compostables, recyclables, and biodegradable materials to support eco-friendly initiatives.

Packaging Testing Costs vs ROI

Typical Packaging Testing Cost Breakdown by Type: Overview of expenses related to different testing methods.

Factors Affecting Cost: Includes test complexity, material type, and industry requirements.

Cost-Benefit Analysis for Preventive QA Investment: Demonstrates how upfront testing reduces costly failures and recalls.

Kimecopak’s Approach to Sustainable Packaging QA

Tailored Evaluation of Packaging Process: Customized testing strategies to meet client needs.

Use of Standardized and Custom Testing Protocols: Balances compliance with innovation.

Integration of Sustainable Material Sourcing and Validation: Supports eco-friendly packaging development.

Continuous Improvement Through Test Data: Uses results to enhance packaging quality over time.

Conclusion

Packaging testing is a cornerstone of product success, ensuring safety, durability, and regulatory compliance while advancing sustainability goals. For businesses seeking expert support in eco-friendly food packaging testing in Canada, Kimecopak offers comprehensive, tailored solutions to help you meet quality assurance and environmental objectives. Contact Kimecopak today to elevate your packaging standards and drive product excellence.